My Ph.D. Program

Civil and Structural Engineering

❝ The scientific man does not aim at an immediate result. He does not expect that his ideas will be readily taken up. His work is like that of a planter, for the future. His duty is to lay the foundation for those who are to come and point the way. ❞

Industrial Context

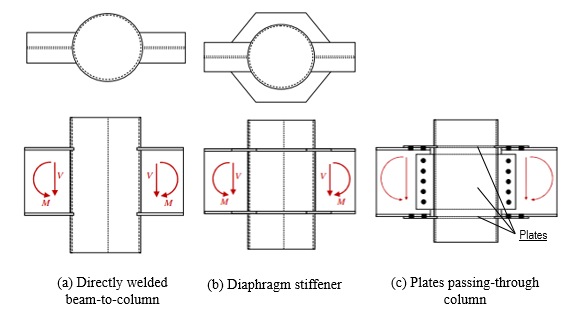

The connection of I-beams to hollow structural columns is quite delicate in building construction. One of the conventionnal solutions that is offered is to directly weld the I-beam to the hollow column (see Figure – a). However, this solution is too flexible and the resisting moment is limited. This type of connection can be strengthened by adding external diaphragms (see Figure -b) which increase the stiffness and the moment of resistance but also the cost of manufacture and the size.

The assembly can still be improved by allowing the I-section to pass through the tube and welding it to the tube (see Figure -c). Laser technology makes it possible to perform this type of cutting.

The LASTTS ( LASer Technology for Tubular Structures) is an european project that aims to investigate different types of two-way and four-way moment resisting open-to-HSS (Hollow Structural Sections) connections obtained using an innovative “passing-through” approach. The project is an extension of the primary work done in the European research project LASTEICON (LASer TEchnology for Innovative CONnections in steel construction), which focused essentially on open-to-CHS connections (for Circular Hollow Sections).

The previous EU-RFCS LASTEICON project showed that joint configurations fabricated using laser cutting technology (LCT) were superior in terms of resistance and stiffness from the tubular joint options obtained by conventional manufacturing techniques (directly welded, through diaphragm, external diaphragm and open section).

The final impact will be to let engineers and architects exploit the outstanding structural and architectural properties of steel hollow sections in the future building projects.

The European project LASTTS, which started in July 2021 for a duration of 42 months, aims at answering these questions. The subject of my PhD thesis is part of this framework.

Ph.D. Subject

The objective of my PhD program is to develop a calculation method for these types of connections by laser cutting, providing design guidelines as well as worked examples. These methods should provide the initial rotational stiffness, bending moment resistance and rotational capacity for a design in accordance with the principles of Eurocode 3 and 4. The developed analytical model will be validated by comparison with results of finite element analysis and experimental tests.

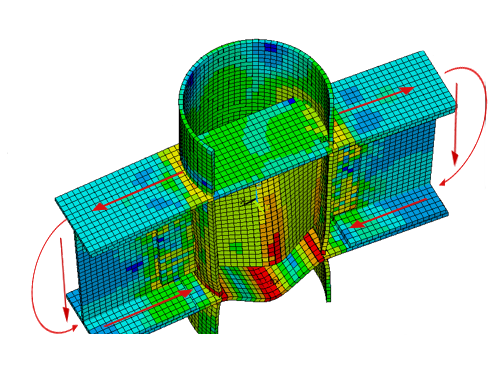

It will be necessary to develop a finite element model on ANSYS to account for the behavior of these assemblies. Volumetric and contact elements will be used. The behavior of the steel will be elastoplastic by integrating damage evolution to model the initiation and propagation of cracks in the welding zones.

The INSA of Rennes will be in charge of the dimensioning of the test campaigns of the project. We will carry out 12 tests in our laboratory on metallic and steel-concrete composite assemblies of square tubes at scale 1 (under static and cyclic loading).

This project is composed of a consortium of 16 European partners, I bet you can guess in what language the meetings are conducted, namely :

| No. | Partner | country | People |

|---|---|---|---|

| 1. | Politecnico di Milano | Italy | Carlo A. Castiglioni, Alper Kanyilmaz, Kevin Useche, Lorenzo Sgubbi, Martina Chierici |

| 2. | Universita di Pisa | Italy | Andrea Piscini, Francesco Morelli, Sara Del Genovese, Walter Salvatore |

| 3. | Universita di Trento | Italy | Oreste Bursi, Gabriele Zanon, Shervin Safaei |

| 4. | MOVISID SPA | Italy | Danilo De Giovanni, Massimo Latour |

| 5. | ADIGE-SYS SPA | Italy | Alberto Val, Maurizio Sbetti, Marco Brugnolli |

| 6. | INSA de Rennes | France | Maël Couchaux, Mohammed Hjiaj, Mouad Madhouni |

| 7. | CTICM | France | Bin Zhao, Christophe Thauvoye, Gisèle BIHINA |

| 8. | Briand CM | France | Nicolas Henneton, Charrier |

| 9. | ArcelorMittal Lexy | France | Gorka Iglesias, Sylvain Santrisse, Unai Aramburu |

| 10. | RWTH Aachen | Germany | Benno Hoffmeister, Cristian Vulcu, Simon Schaffrath |

| 11. | GREGULL + SPANG | Germany | Marian Kempkes |

| 12. | Vallourec GMBH | Germany | Ralf Hojda, Jeannine Van Treeck |

| 13. | Instituto Superior Tecnico | Portugal | Jorge Proenca, Luis Calado, Miguel Correia |

| 14. | GRID International | Portugal | Jose Pedro, Monica Fonseca, Andrè Biscaya |

| 15. | Universiteit HASSELT | Belgium | Herve Degee, Ilse Haeldermans, Rajarshi Das |

| 16. | Bureau GREISCH | Belgium | Thibaud BASTIN, Vincent De Ville, Yves Duchene |